The Design and Engineering teams here have been hard at work with a brand new custom designed gating system for a Florida Park. We’re not allowed to unveil who it’s for yet, but rest assured, it’s one you will have heard of.

The gating system is one of the biggest we have ever built and sets new standards in safety, throughput and reliability. They are designed and built to the worldwide theme park safety standards of BSEN 13814, but with some additional improvements we have designed into further minimise the risk of trapping little fingers and arms whilst the gates are in operation.

They have also been strengthened and improved throughout to be able to work perfectly for a minimum operating life span of 25 years or more with reasonably minimal maintenance. With the duty cycles the gates work to in the bigger parks, this will mean many, many millions of passengers passing through them on their way to an all new (and enormously exciting) ride.

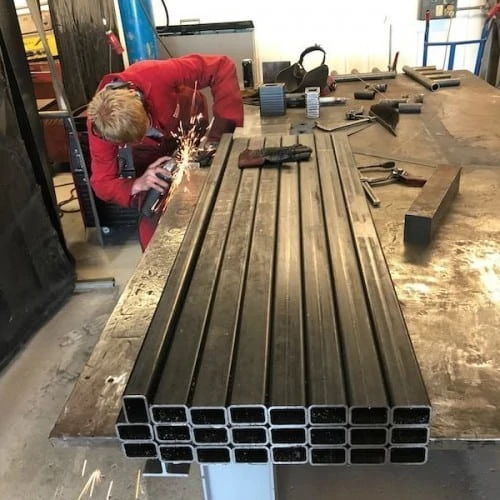

So we thought you’d like to see how they are built and what goes into a gating system as it grows from cut metal to fully functioning and operating gating system.

We have already designed and installed systems throughout the US with one of our favourites being another custom shotgun gates system for the Orlando Eye, which you can see in the image above.

The laser cut parts come into the workshop for the shotgun gates for Orlando

All of the pieces are cut to size, prepped and cleaned up ready for assembly for the shotgun gates for Orlando

All of the individual components for the Shotgun Gates for Orlando are brought together in a purpose design and millimetre perfect jig, before being tacked welded together

The shotgun gates are tack welded frame is tested again for accuracy and ensure a perfect fit with related components

Before being welded up and cleaned again

All of the welded components on the gating system for Orlando are tested and cleaned again before their next stage

The internal structure of the gates are then covered with a fully plated cover to finish and ready for Powder coating

+44 (0)115 932 7082

+44 (0)115 932 7082 enquiries@garmendale.co.uk

enquiries@garmendale.co.uk